Use

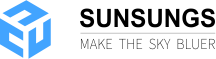

Dual alkali FGD is a process of adopting sodium baseddesulfurizer to desulfurizationin the tower, after desulfurization result reduction regenerationby Ca (OH) 2, regeneratethe absorbent can recycle. Due tostrong alkaline sodium based desulfurizer, reaction product solubility after absorbing carbon dioxide. It won't cause satiety, crystallization and dirtyjams equipment problems. Dual alkali desulfurizationprocess reduces the investment and operation cost, more suitable for middle and small boiler, furnacedesulfurization renovation.

Reaction principle

2NaOH+SO2--Na2SO3+H2O

Na2SO3+SO2+H2O--2NaHSO3

Ca(OH)2+Na2SO3--2NaOH+CaSO3

Ca(OH)2+2Na2SO3--Na2SO3+CaSO3▪1/2H2O+1/2H2O

Because the smoke contains oxygen, but also thefollowing side effects occur:

Ca(OH)2+Na2SO3+1/2O2+2H2O--2NaOH+CaSO4▪H2O

Take off the sulphur in the form of calciumsulfite and calcium sulfate precipitation, then pump into the gypsumdehydration processing system or directly pile or abandoned. Regeneration of NaOH.

Process description

The flue gas fromboiler and furnace after decontamination, enter into the desulfurization tower from the bottom. And in the tower inside, SO2 from flue gas fully absorb and reaction with the alkali liquor spray down from the top of tower, After desulphurization washing afterdividing net flue gas sulfur precipitation in the form of calcium sulfite andcalcium sulfate, then pump into the gypsum dehydration processing system ordirectly pile or abandoned. Regenerationof NaOH.